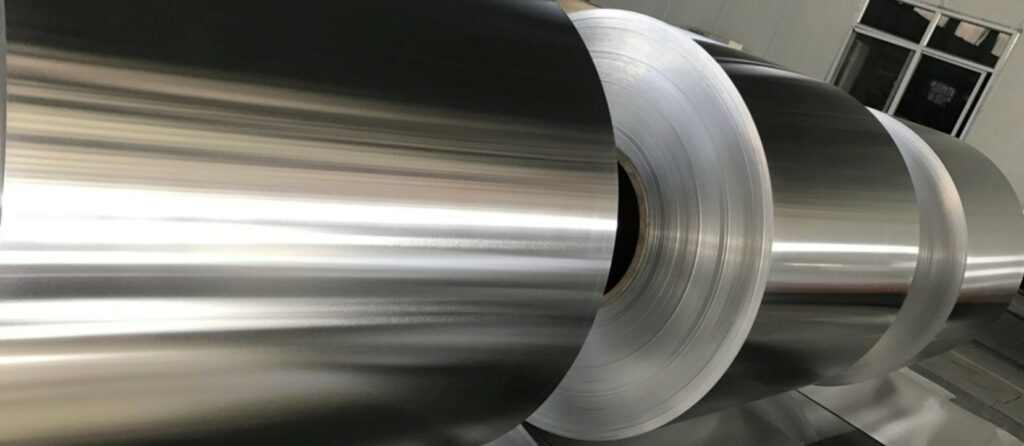

1050 aluminium alloy is an aluminium-based alloy in the “commercially pure” wrought family (1000 or 1xxx series). As a wrought alloy, it is not used in castings. Instead, it is usually formed by extrusion or rolling. It is commonly used in the electrical and chemical industries, on account of having high electrical conductivity, corrosion resistance, and workability. 1050 alloy is also sometimes used for the manufacture of heat sinks, since it has a higher thermal conductivity than other alloys. It has low mechanical strength compared to more significantly alloyed metals. It can be strengthened by cold working, but not by heat treatment.

Alternate names and designations include Al99.5, 3.0255, and A91050. It is described in the following standards:

ASTM B 491: Standard Specification for Aluminum and Aluminum-Alloy Extruded Round Tubes for General-Purpose Applications

ISO 6361: Wrought Aluminium and Aluminium Alloy Sheets, Strips and Plates

Chemical composition

The alloy composition of 1050 aluminium is:

Aluminium: 99.5% min

Copper: 0.05% max

Iron: 0.4% max

Magnesium: 0.05% max

Manganese: 0.05% max

Silicon: 0.25% max

Titanium: 0.03% max

Vanadium: 0.05% max

Zinc: 0.05% max

Hi, this is a comment.

To delete a comment, just log in and view the post's comments. There you will have the option to edit or delete them.

Hello, I want to work in your company on a voluntary basis, can you offer me anything?

a little about me:https://about.me/soniaj.robinson

Hi, Sylvia.

Thank you for your interesting in our company.

May I know what you can do for us as a voluntary basis?

Best regards,

Alumimart

Do you have any kind of pointers for creating write-ups? That’s

where I always battle as well as I just wind up looking vacant display for long period of time.

Hi Nereida,

Thank you for your message.

No, I don’t have.

Best regards,

Alumimart