Aluminum sheet can be formed and welded into simple shapes using technology similar to that for steel sheet-metal. Aluminum has excellent thermal conductivity but is much softer and less stiff than stainless steel. As a result, aluminum molds tend to have thicker walls than carbon or stainless steel molds. Aluminum is easily machined and can be relatively easily textured with grit blasting and chemical etching.

Aluminium is lightweight and has a good strength to weight ratio. Aluminium sheets can be cut using a jigsaw with the correct blade, on a guillotine, or very thin sheets can be cut using a sharp blade or tin snips. Aluminium Sheet is straightforward to form or bend using hand tools or a sheet metal bending brake. Fabrication is easy as sheet products can be welded with the correct skills and equipment and can be readily joined using rivets and other traditional fasteners. Aluminium is very easy to drill and machine which makes it an ideal choice for a wide range of projects.

Aluminium Sheet is the most widely used form of aluminium. It is commonly used for light fabrications, truck and trailer repairs, car body panels, enclosures, machine building, and extensively in construction, aerospace and defense applications.

Aluminium Mart offers a wide variety of sheeting to meet customer's every need, all readily available for a speedy dispatch and delivery. Common widths of Aluminium sheet and plate is 1000mm, 1250mm and 1500mm. Common lengths are 2000mm,2500 mm and 3000mm respectively. Our Aluminium Sheet can be cut as per customers' requirement.

Aluminium Sheets can be supplied standard mill finish, and also are available as painted sheet, Stucco sheet, Roof Sheeting, Tread Plate and Treadbrite.

Aluminium Sheet Production Process:

The ingot casting - DC( Direct Chill Casting )- CC (Continuous Casting)-Annealing - Packaging

Aluminium Sheet Supply Range:

Alloy type: 1050 1060 1100 3003 3004 3105 3105 5005 5052 5454 5754 5083 8001

Technology: Casting / CC / DC

Temper: F O H12 H22 H14 H16 H18 H32 H34 H36 H38 H111 H321

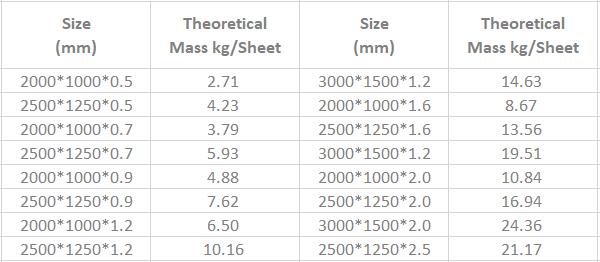

Thickness Range: 0.5mm-2.5mm, anything thicker is considered to be Plate.

Aluminium Sheets Size and Theoretical Mass as reference:

Aluminium sheet metal is an excellent substrate for painting and powder coating, polyester powder coated aluminium with correct pretreatment is used in architectural applications with guarantees in excess of 25 years.

The table below shows the various grades of aluminium alloys:

| Aluminium Series | Alloying Elements | Grade References |

| 1000 Series | Pure Aluminium | 1050 / 1200 |

| 2000 Series | Copper | 2014 |

| 3000 Series | Manganese | 3013 |

| 4000 Series | Silicon | 4343 / 4015 |

| 5000 Series | Magnesium | 5251 |

| 6000 Series | Magnesium | 6063 / 6082 |

| 8000 Series | Others |

Typical Alloys for Metal Sheet as following:

Aluminum Alloy 1050 for Metal Sheet

| Composition: | Al99.5 |

| Characteristics Properties: | Very good atmospheric corrosion resistance. Very good workability. High thermal and electrical conductivity (preferred alloy 1350). Attractive appearance, high reflectivity. Suitable for decorative anodising. Very good weldability. Low mechanical properties. |

| Applications: | Packaging: containers, foils, collapsible tubes, radiator tubes, wide jar closures, printing plates (offset). Strip for heat exchanger, boilermaking. Insulation foils. Kitchenware. Chemical and food industry equipment, containers. Automotive trim, light reflectors. Architecture. Vessels, piping. |

3003 Alloy Aluminum Sheet Roofing

| Composition: | Al 1.3Mn Cu |

| Characteristics Properties: | Very good resistance to atmospheric corrosion. Very good weldability. Good formability by pressing, drawing and roll forming. Medium strength alloy. Better mechanical properties (in particular at elevated temperatures) than 1xxx-alloys. Properties very close to those of 3103. |

| Applications: | Building industry: roofing and sidings, acoustic ceilings, corrugated sheets. Chemical and food industries: storage tanks, pipes, metal work. Equipment for heating and cooling: heat exchangers, air condition evaporators, motor vehicle radiators, freezer linings. Home appliances: cooking utensils, bakery moulds, office equipment. Tubing, piping. Packaging: containers, closures. Cladding alloy. |

5050 Alloy Aluminum Sheet Roofing

| Composition: | Al 2.5Mg Cr |

| Characteristics Properties: | Very good corrosion resistance to seawater and marine and industrial atmosphere. Very good weldability. Good cold formability. Medium high strength alloy with a strength slightly higher than 5251. Medium high fatigue strength. |

| Applications: | Boilermaking, containers. Nameplates, traffic (road) signs, architectural paneling. Welded tubes, chemical industry, irrigation, desalination units. Pressure vessels. Rivets. |

6061 Aluminum Sheet Roofing

| Composition: | Al 1.0Mg 0.6Si Cu Cr |

| Characteristics Properties: | Very good corrosion resistance. Very good weldability; reduced strength values in the zone of welding. Heat treatable alloy. Medium high strength alloy with a strength higher than 6005A. Medium fatigue strength. Good cold formability in the temper T4. Not suitable for very complex cross sections. |

| Applications: | Heavy duty structures in rail coaches, truck frames, ship building, bridges, military bridges, aircraft, piping, pylons and towers, transportation, boilermaking; Motorboats, aerospace applications, helicopter rotor skins; Rivets. |

High Quality Aluminum Alloy Metal Sheet 7075 for Aircraft

| Composition: | Al 5.6Zn 2.5Mg 1.6Cu Cr |

| Characteristics Properties: | Heat treatable very high strength alloy with a strength slightly lower than 7010. Very high fatigue strength. Joining preferably by rivets, adhesives or screws. Corrosion protection is recommended also in outdoor atmosphere. |

| Applications: | Aircraft and military highly stressed structural components. Rolling stock for machine parts and tools (for rubber and plastics). Ski poles, tennis rackets, screws and bolts, nuts. Rivets. Nuclear applications. |